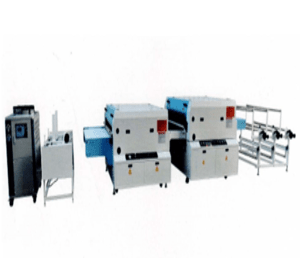

Composite Lamination Unit Machine

Applicable Industry: Woven upper composite, insole shoe lining composite, leather breathable film composite.

Configuration

1. Imported anti-static seamless belt.

2. Imported high temperature resistant silicone roler. 3. Imported nicket chromium wire mica sheet.

4. Imported temperature controller, solid state relay temperature control.

5. Large 3 hp ice water machine refrigeration. 6. Frequency converter frequency conversion motor speed regulation.

Features

1. The split healing wind cooling design is adopted. the heating area is extended to 1400mm, the heating speed of 9 heating plates is fast and the temperature is stable. The refrigaration area is extended to 1400mm. B refrigration boards and the cooling affect is strong, which can make the material reach a temperature below room temrature in s short time to increase the adhesion and the durability of the material.

2. Use a thick silicone stick to poress to obtain a uniform and balanced pressure. 3. The double frequency converter and the double frequency conversion motor are separetly controlled and the speed and speed can be adjusted arbitarily.

4. The ring shaped belt walking method does not roll the material and will not damage the belt. 5. Imported electrical components have a long service life and temperature control and speed control are more accurate.

6. The heating speed of imported nicket chromium heating mine is 25% faster than that of ordinary electric heating tubes. The thermal insulatin effect of glass fiber wool insulatin layer is three times higher than that of material such as rock wool or aluminium silicate commonly used in the market

Back